| Payment Type: | L/C,T/T,D/P,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,FCA,CPT |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 90 Days |

Basic Info

Model No.: CHG-G225/320P-B

Portable: Non Portable

Form: Other

Application: Industrial

Type: Industrial High-definition X-ray Detector

Certification: CE, ISO

Customized: Customized

Alarm Form: Display Alarm

Working Way: Continuous Working

Purpose: Inspect Any Defect In Pipe Connection

Pipe Thickness: 3-13mm

Inspection Pipe Diameter Range: 54-104mm

Voltage Range: 225KV/320KV

Additional Info

Packaging: WOODEN PACKAGE

Productivity: 100

Brand: JUXING

Transportation: Ocean,Land,Air

Place of Origin: DANDONG

Supply Ability: 100

Certificate: ISO9001

HS Code: 90221990.00

Port: DALIAN,SHENYANG,BEIJING

Product Description

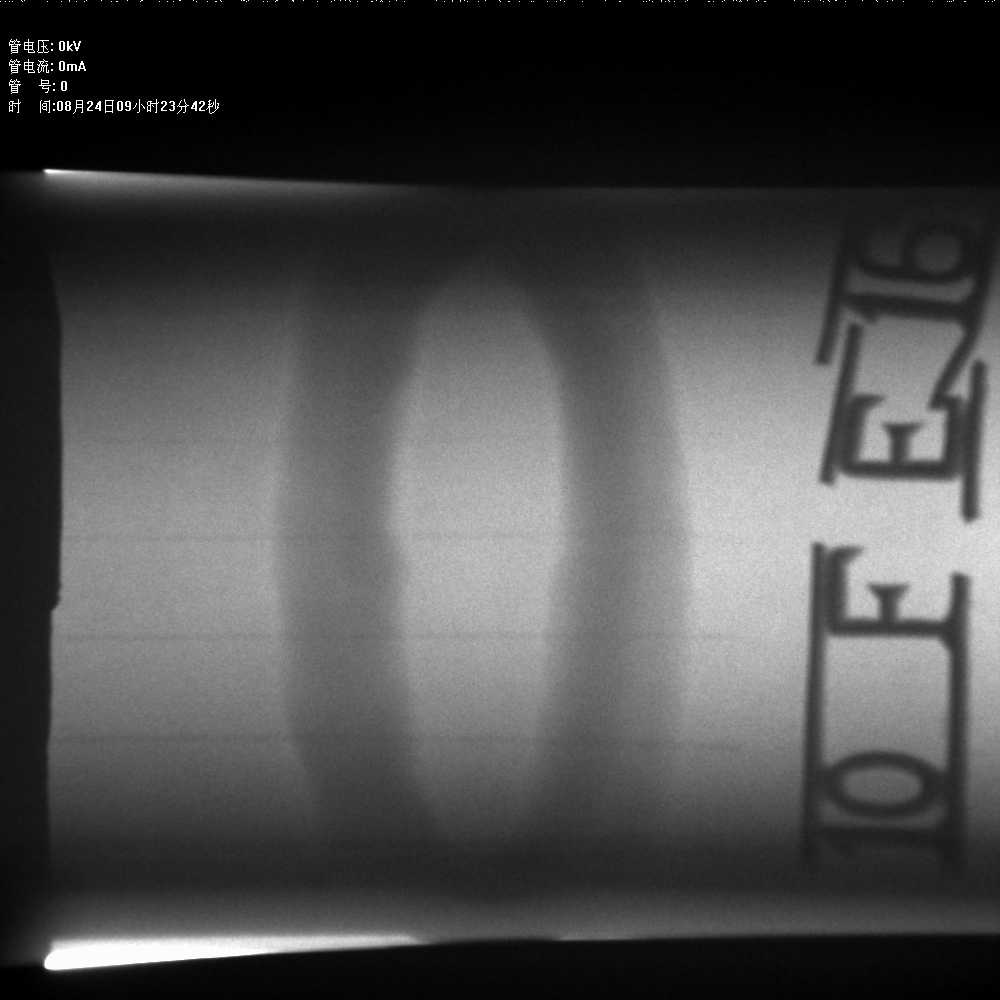

Boiler Pipe Welding Real Time Radiography Inspection System

The Real Time Radiography system which Inspect Boiler Pipe Welding is specified for the inspection of small diameter(boiler) butt welded pipe girth weld. It is mainly composed by X-ray machine, digital radiography unit, image processing&storage unit, mechanism unit and electric unit and protection room and monitor unit.

Dynamic noise detection technology, more efficient detection

Static automatic noise reduction technology, covenient operation

Welding Steam marking

Flat-panel detector

Built-in rotation mechanism, debugging-free installation

Fully digital system solution

24hours continuously working

System resolution: 30LP/cm

System parameter:

Pipe diameter: 54-104mm(CHG-G225/320P-B)

Pipe thickness: 3-13mm

Rotating device: 1-6 rotation/min adjustable

Pic of unit:

© 2019 CHINA WAY. All Rights Reserved. Dandong Nondestructive Testing Equipment Co., Ltd., Inc. All rights reserved. site map. sitemap.html